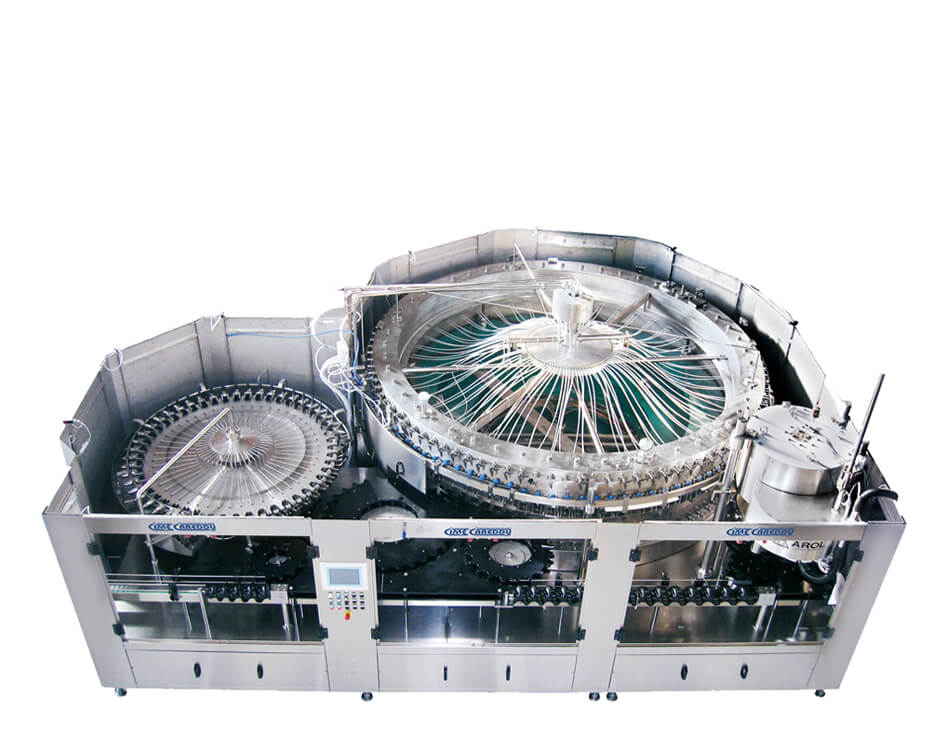

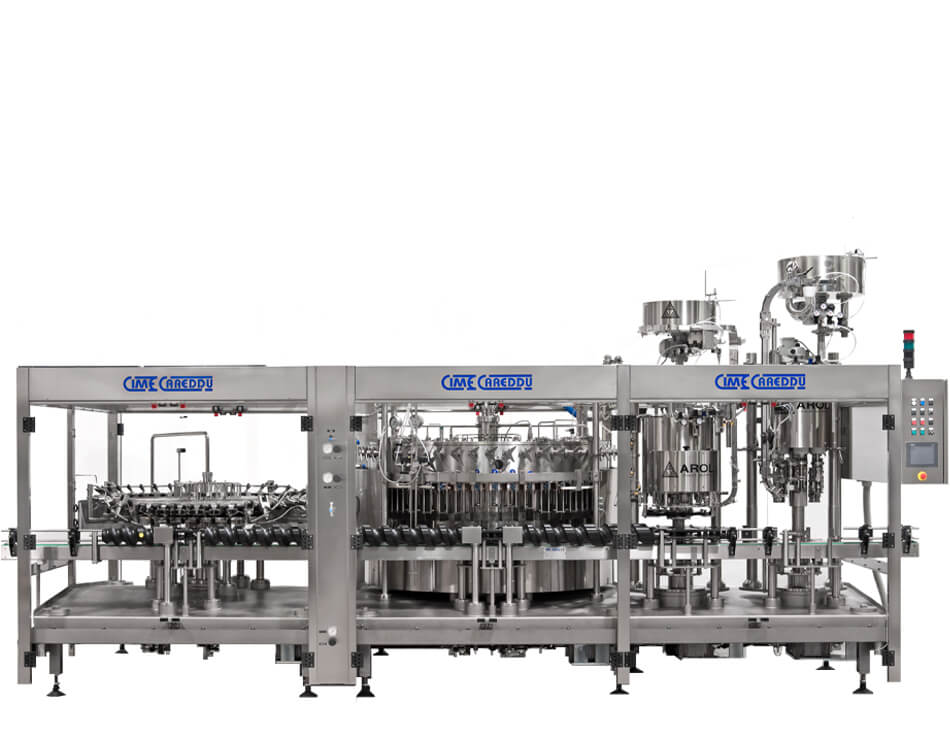

The GOLD line is designed for the filling of glass, PET, and aluminium bottles with carbonated products.

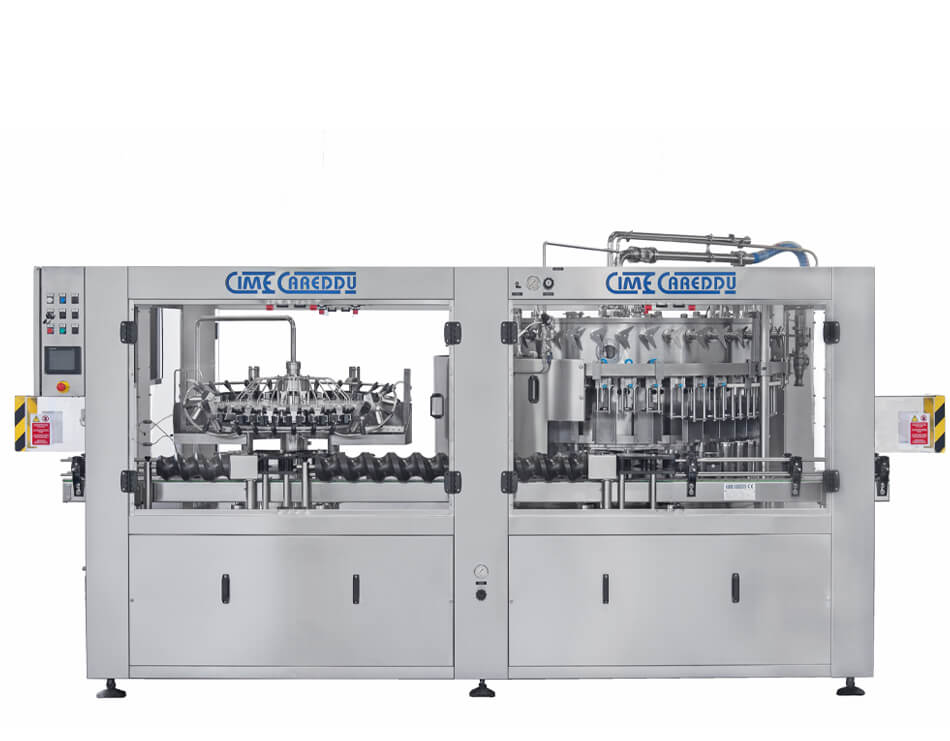

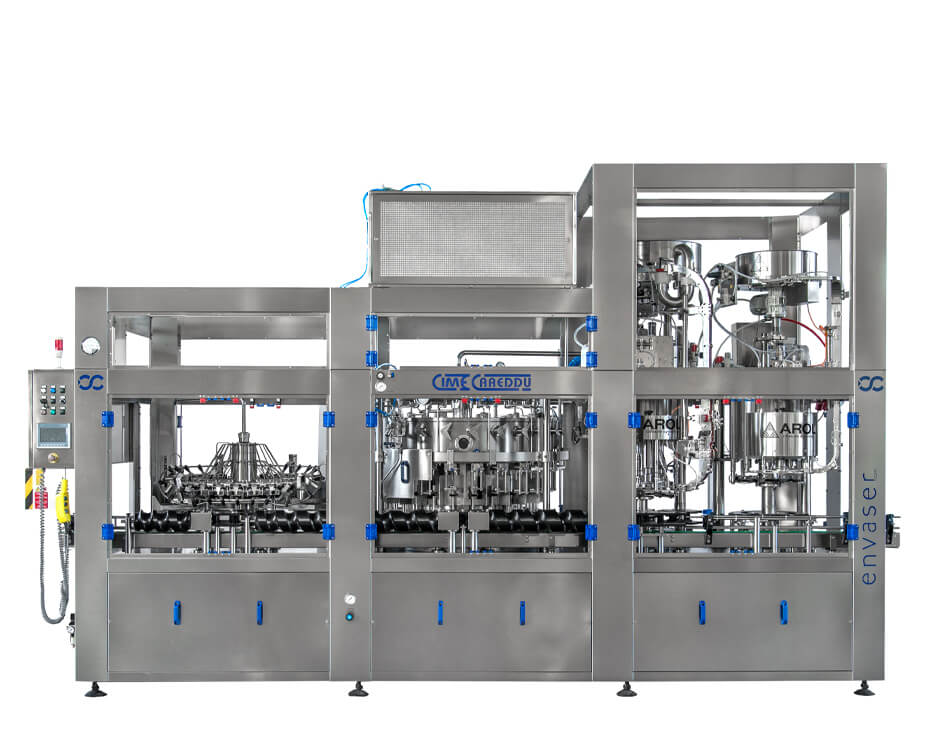

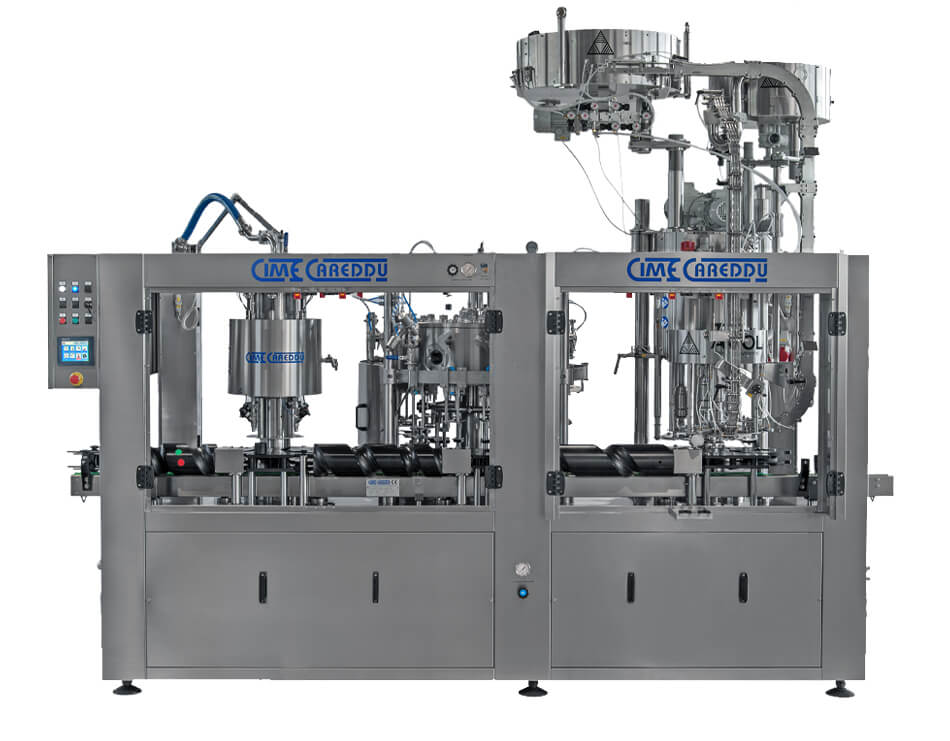

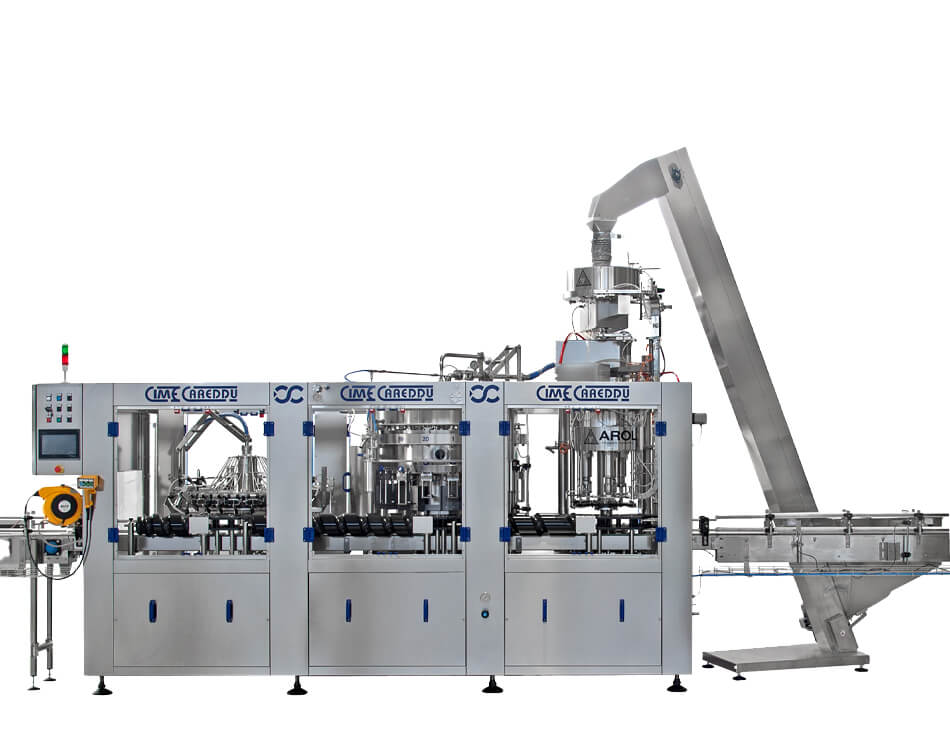

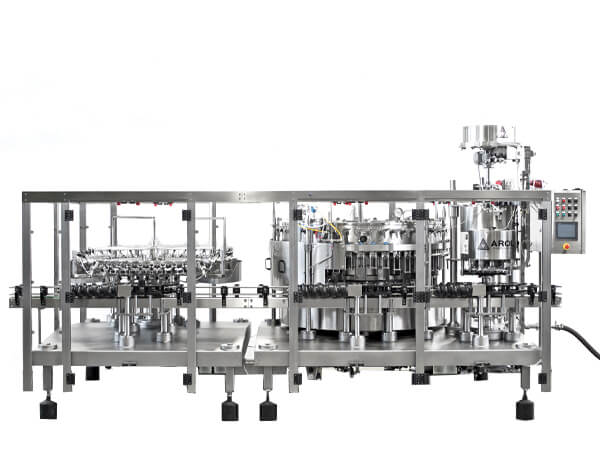

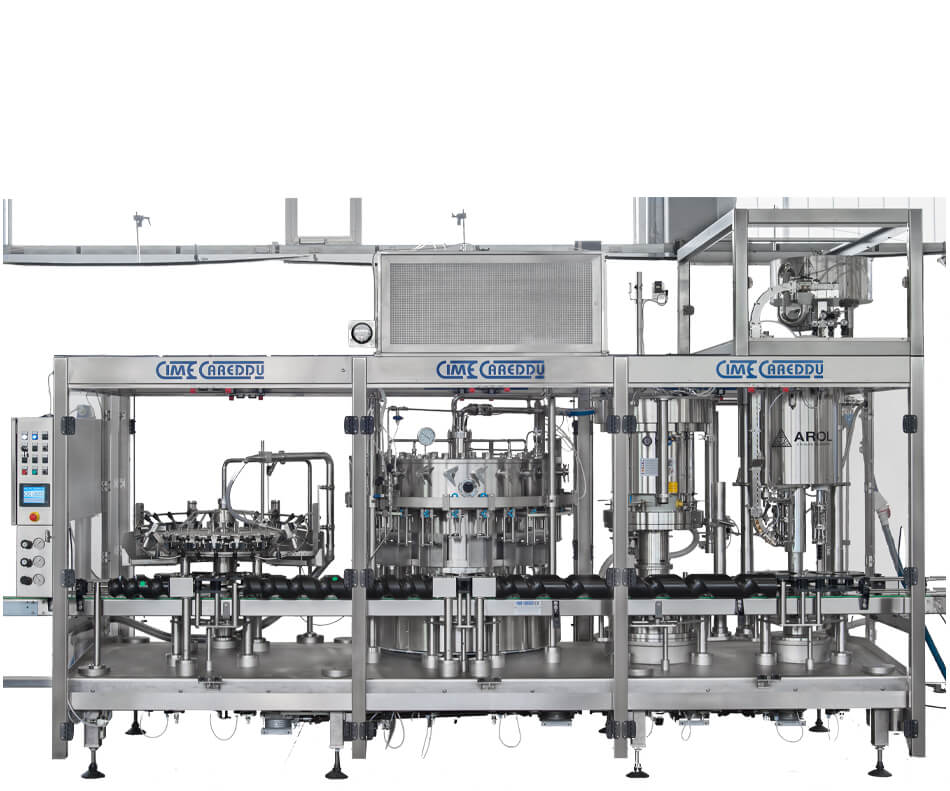

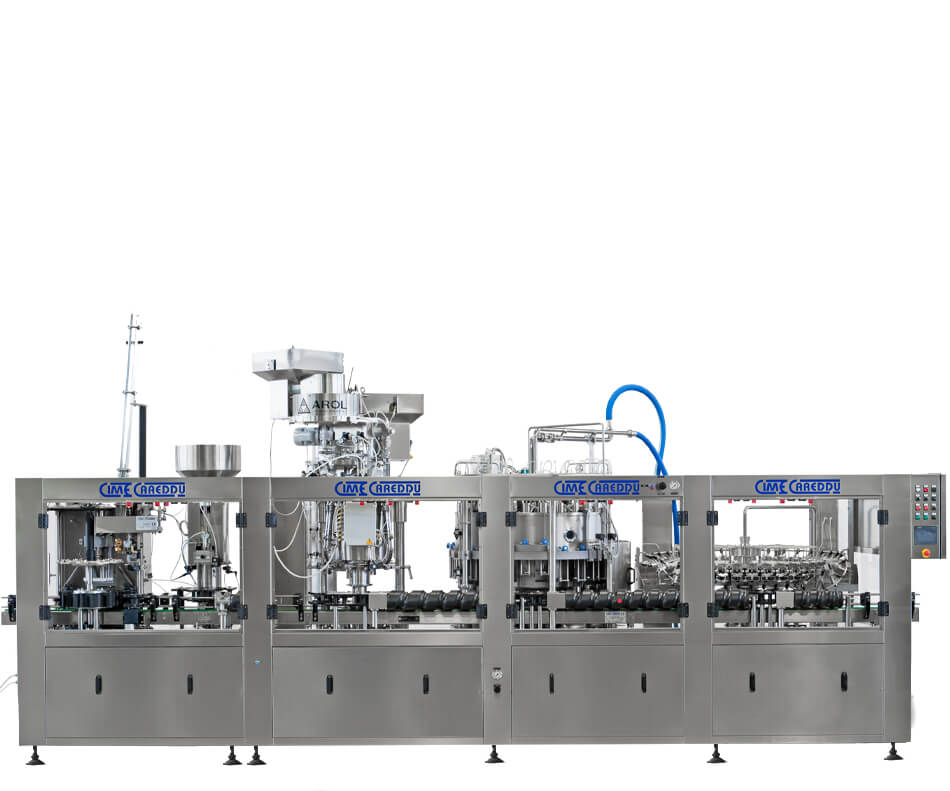

Depending on its configuration, the monoblock can perform the operations of rinsing, filling, and capping.

Our production is able to meet the needs of 1,000 to 18,000 bottles per hour, with a specific valve according to the product to be bottled

The parts in contact with the product are made of AISI304 stainless steel (AISI 316 on request) and the parts of plastic material are FDA certified.

All details of the filling valve are specifically designed to ensure an optimal quality of filling, thanks to the insignificant level of oxygen pick up, high levels of hygienic safety, and the maximum simplicity in the operations of mounting and demounting.

Various types of filling valves are available depending on the product to be processed.

The GOLD monoblocks are fully automated and the operator is required to perform only the loading/discharge of bottles and closures